|

|

DEFINITION

OF INTERLINING

Interlining

is the general name of the textile lining used in dry-clean garments as

well as in washable clothes, dresses, blouses and shirts. Interlining

is used both in larger parts of the said items such as the shoulders,

yokes, front panels, foldable and joinable parts and also in smaller

parts like the collars, waists and cuffs.

POINTS

TO BE TAKEN INTO CONSIDERATION WHEN SELECTING LINING

1-

Compatibility of the lining and the type and finish of the fabric.

2- Compatibility of the lining with the purpose of the garment and the part

of the garment in which it is to be used.

3- Compatibility with the characteristics

of the desired feel of the cloth.

4-

Compatibility with the desired resistance to washing, dry cleaning,

ironing and drying.

5-

Compatibility with the type, cut and colour of the garment.

6-

The ability of the lining once put into place not to change the quality

of the fabric.

7-

The importance of carrying out preliminary tests on the fabric sample.

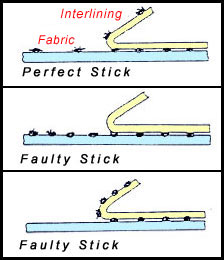

POINTS

TO BE TAKEN INTO CONSIDERATION WHEN STICKING THE LINING

The

points to be taken into consideration during this process can be listed

as below:

a. First and foremost, you

should be sure that the appropriate type of lining is used for the

fabric.

b. The fabric and the lining

should be placed one on the other lengthwise in such a way that their

directions match.

c. Sufficient heat should be

applied for the sticking.

d. You should perform in

adequate pressure degrees. The low pressure decreases the heat transfer

and permeability and consequently the strength of adhesion, resistance

to washing and dry cleaning are reduced. To the contrary, high pressure

causes the fabric to show the traces of glue and this effects touch,

resistance to washing and dry cleaning negatively.

e. Sufficient time for the

sticking process should be applied.

f. In the event that a

pressing machine does not exist in the workplace and the process will be

done with an iron, the iron should be pressed on the fabric without

rubbing and without using any steam and the pieces should be processed

one by one.

g. The dimensions of the

lining to be applied should not be larger than the dimensions of the

fabric. Otherwise, the excess lining soils the tape while passing

through the machine and the glue is transferred onto the next piece of

fabric. |

|

TEST METHODS APPLIED

TO INTERLINING

1-

Type of fibre and glue

2- Quantity of the fibre and glue

3- Thickness

4- Feel

5- Resistance

6- Change in the dimensions of the lining (after application of

heat and steam)

7- Strength of separation (degree of

adhesion).

8-

Resistance to washing, dry cleaning and steaming.

9-

Water- resistance

|

|